-

Nancy Yi

Hi there! Welcome to my shop. Let me know if you have any questions.

Nancy Yi

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

How to Make Your Products More Durable and Aesthetically Pleasing?

2025-11-06 15:11:06

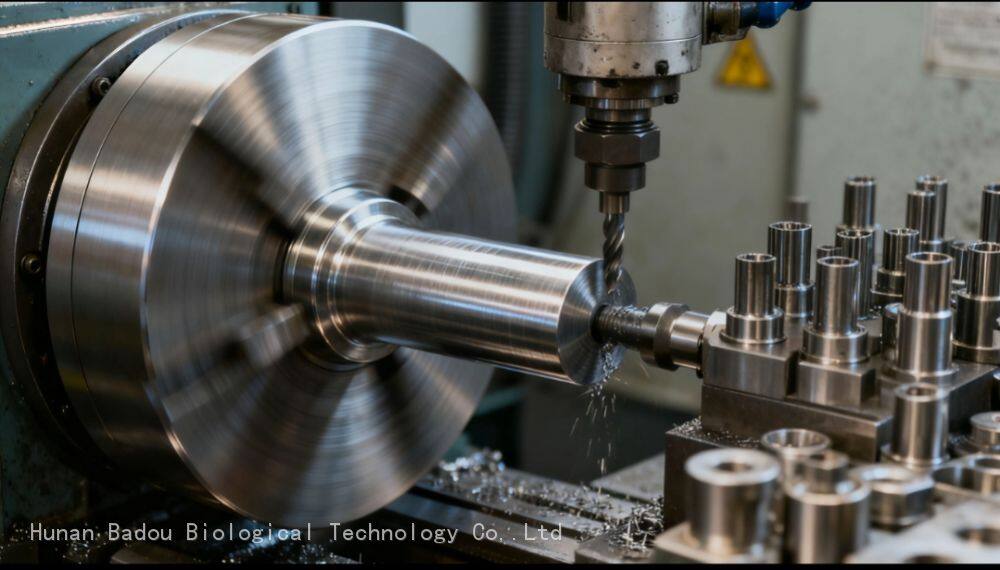

A Deep Dive into Hardware Surface Treatment Processes: How to Make Your Products More Durable and Aesthetically Pleasing?

Have you ever wondered why some hardware is as shiny as a mirror while others are matte and understated? Why do some remain corrosion-free for years under outdoor exposure, while others quickly rust? The answer lies in - surface treatment processes. Surface treatment is not only for enhancing appearance but also a key method to improve the corrosion resistance, wear resistance, and service life of hardware products. This article will reveal several common hardware surface treatment processes, analyzing their pros, cons, and application scenarios.

1. Electroplating

- Principle: Using electrolysis to deposit a thin layer of another metal or alloy onto the metal surface.

- Common Types: Zinc (Zn) plating, Chromium (Cr) plating, Nickel (Ni) plating, Copper (Cu) plating, Gold (Au) plating, Silver (Ag) plating.

- Advantages:

- Zinc Plating: Low cost and good corrosion resistance, making it one of the most common anti-rust treatments.

- Chromium Plating: Extremely high hardness, excellent wear resistance, and a mirror-like, bright surface with outstanding decorative effect.

- Nickel Plating: Provides a smooth, flat surface with good corrosion and wear resistance, often used as an intermediate layer.

- Disadvantages:

- Some processes (like chromium plating) contain heavy metals, posing environmental concerns.

- The coating is relatively thin and may peel off under severe friction.

- Typical Applications: Screws, nuts, tools, bathroom faucets, automotive parts.

2. Spraying

- Principle: Uniformly spraying paint (liquid or powder) onto the hardware surface using a spray gun to form a protective film.

- Common Types: Spray painting (liquid coating), Powder coating.

- Advantages:

- Powder Coating: Thick coating, excellent corrosion and impact resistance, wide color range, and environmentally friendly (solvent-free).

- Spray Painting (Liquid): Flexible application, suitable for complex shapes, and can achieve various gloss effects (high-gloss, matte, metallic).

- Disadvantages:

- Coating hardness is lower than electroplating, making it prone to scratches.

- Surface finish is generally not as good as electroplating.

- Typical Applications: Outdoor furniture, fitness equipment, electrical enclosures, security doors, lamp housings.

3. Anodizing

- Principle: Primarily for aluminum and its alloys. It uses electrolysis to form a hard, wear-resistant, and corrosion-resistant oxide film on the aluminum surface.

- Advantages:

- The oxide film is hard and wear-resistant.

- A wide range of colors (black, red, gold, etc.) can be achieved through electrolytic coloring.

- Environmentally friendly, with the film layer tightly bonded to the substrate, making it difficult to peel off.

- Disadvantages:

- Only applicable to aluminum and its alloys.

- Colors may fade slightly under prolonged sunlight exposure.

- Typical Applications: Aluminum alloy doors and windows, curtain walls, mobile phone casings, laptop casings, aerospace components.

4. Passivation

- Principle: A chemical method to form a dense passivation film on the metal surface (such as stainless steel, aluminum) to isolate air and moisture and prevent corrosion.

- Advantages: Simple operation, low cost, and can effectively improve the corrosion resistance of stainless steel in specific environments.

- Disadvantages: The film layer is thin and offers limited protection against physical wear.

- Typical Applications: Stainless steel tableware, medical devices, food processing equipment.

5. Polishing

- Principle: Using mechanical or chemical methods to remove burrs and scratches from the metal surface, making it smooth and flat to achieve a mirror or matte finish.

- Advantages: Greatly enhances the product's aesthetics and texture, often used for products with high decorative requirements.

- Disadvantages: Does not provide rust resistance and usually needs to be combined with other anti-rust processes (such as electroplating, spraying).

- Typical Applications: Decorative hardware, lighting fixtures, bathroom accessories, crafts.

Conclusion and Selection Advice

- For ultimate rust prevention: For outdoor products, hot-dip galvanizing or powder coating is preferred. For stainless steel products, passivation can be considered.

- For high-gloss and wear resistance: Tools, bathroom faucets, etc., can choose chromium plating.

- For color and texture: For aluminum alloy products, anodizing is the first choice. For a wide range of color options, powder coating is available.

- For environmental friendliness and durability: Powder coating and anodizing are good choices.

- For decoration: Polishing followed by electroplating or spraying yields the best results.

Choosing the right surface treatment process is a crucial step in enhancing the added value of hardware products. It not only allows your products to stand out in the fierce market competition but also wins customers' trust in product quality.

#HardwareSurfaceTreatment #Electroplating #PowderCoating #Anodizing #Passivation #Polishing #ProductDurability #BadouBiological #CNCMachining #NancyYi

Tags: Hardware Surface Treatment, CNC Machining, Hardware Parts